Nanocrystalline materials have the advantages of silicon steel, permalloy and ferrite, have excellent comprehensive magnetic properties, possess high saturation magnetic induction intensity, high permeability, low coercivity and excellent temperature stability, especially suitable for high-frequency transformer cores.The working frequency of high-frequency inverters power supply ranges from 20kHz to 50kHz. The ferrite materials used in the traditional transformer cores which have low permeability and low Bs within 100kHz frequency band that result in a large volume and high weight of the cores, and poor temperature stability, which is not suitable for high frequency and high power use.

Characteristics:

High saturate magnetic induction-reduce volume of transformers.

High permeability and low coercivity-improve transformer efficiency, lower exciting power and reduce copper loss.

Low core loss-reduce temperature rise of transformers.

Excellent temperature stability-can work at temperature of -55°C~130°C for long time.

Nanocrystalline materials have the advantages of silicon steel, permalloy and ferrite, have excellent comprehensive magnetic properties, possess high saturation magnetic induction intensity, high permeability, low coercivity and excellent temperature stability, especially suitable for high-frequency transformer cores.The working frequency of high-frequency inverters power supply ranges from 20kHz to 50kHz. The ferrite materials used in the traditional transformer cores which have low permeability and low Bs within 100kHz frequency band that result in a large volume and high weight of the cores, and poor temperature stability, which is not suitable for high frequency and high power use.

Characteristics:

High saturate magnetic induction-reduce volume of transformers.

High permeability and low coercivity-improve transformer efficiency, lower exciting power and reduce copper loss.

Low core loss-reduce temperature rise of transformers.

Excellent temperature stability-can work at temperature of -55°C~130°C for long time.

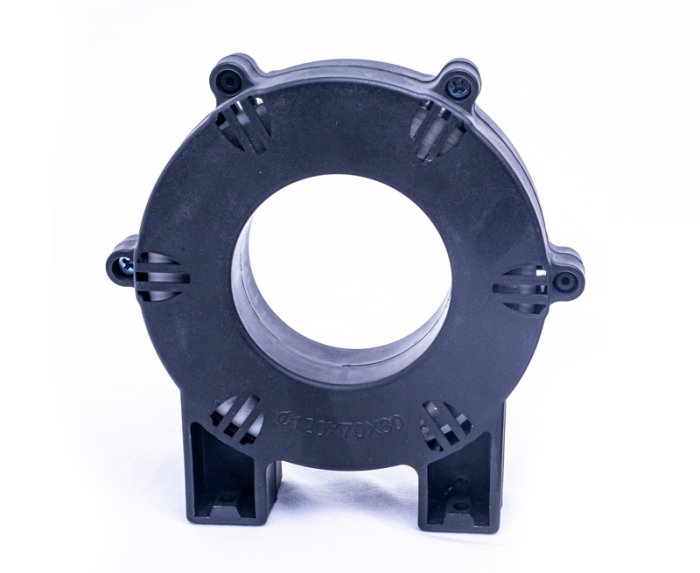

OD*ID*HT(mm) | OD*ID*HT(mm) | Le(cm) | Se(cm2) | (g) | (kw) | (pH) |

ONL-40*25*20 | 45*21.5*24.5 | 10.2 | 1.08 | 83 | <20W/kg | >25 |

ONL-50*32*20 | 53*28*24 | 12.88 | 1.3 | 125 | <20W/kg | [30, 80] |

ONL-64*40*20 | 68*37*24 | 16.33 | 1.73 | 215 | <20W/kg | [25, 80] |

ONL-70*40*20 | 75*39*24.5 | 17.27 | 2.2 | 270 | <20W/kg | [45, 71] |

ONL-70*40*25 | 73*37*29 | 17.27 | 2.7 | 335 | <20W/kg | [40, 90] |

ONL-80*50*20 | 85*44*24 | 20.41 | 2.16 | 317 | <20W/kg | <60 |

ONL-80*50*20 | 85*44*24 | 20.41 | 2.16 | 317 | / | [70, 103] |

ONL-80*50*25 | 85*44*29.5 | 20.41 | 2.6 | 420 | <20W/kg | [50, 110] |

ONL-100*60*20 | 105*54*26 | 25.12 | 2.9 | 540 | <20W/kg | [30, 80] |

ONL-105*60*30 | 109*57*35 | 25.91 | 4.9 | 940 | <20W/kg | [65, 120] |

ONL-120*60*30 | 125*57*35 | 28.26 | 6.5 | 1310 | <20W/kg | [55,105] |

ONL-120*70*25 | 125*67*30 | 29.83 | 4.5 | 960 | <20W/kg | <86 |

ONL-120*70*30 | 125*67*35 | 29.83 | 5.4 | 1160 | <20W/kg | <103 |

ONL-130*80*40 | 136*77*45 | 32.99 | 7.8 | 1852 | <20W/kg | <120 |

Explain | Custom ized production according to customers' requirements. | |||||

Note | Samples for more specifications, please call or message | |||||

Welcome to WeChat

Welcome to WeChat